General Specifications of Masterikizler Framers

- The operator controls the AF via an Industrial19” touch screen computer in the roll former. Easy remote access to the machines via network and /or internet, enables remote diagnosis.

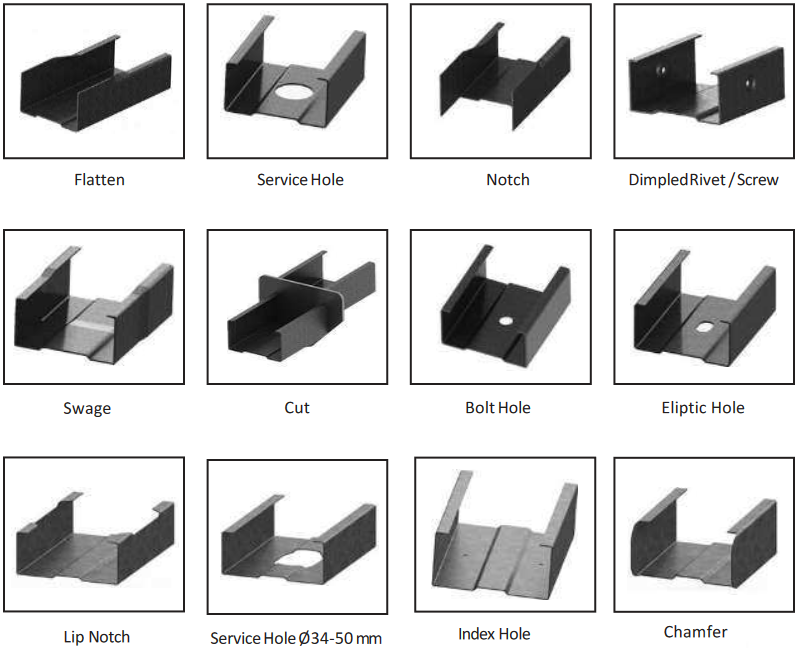

- Cutting the length, service and dimpled rivet/screw holes, notching, flattening, swaging, and forming of the profile is carried out in the roll form and the hydraulic punch/die units with high accurate computer-controlled system.

- The production is fully automatic, and the operator can start-stop, pause and restart at any production stage. Also manufacturing speed can be adjusted during the operation.

- The steel stock feeds into the Roll Former by an automatic de-coiler.

- Moving and factory/site installation of the machines are very fast and easy.

- Training Subjects:

- 3D Design and Detailing Software

- Framer Software

- Machine Control and Frame Manufacturing

- Mechanical Maintenance

- Our quality management system and all our other systems, the profiles and assembly work we produce, have been registered in terms of compliance with the standards.

- Masterikizler Light Steel Framing Machines comply with the structural necessities internally/externally, which carry commercial and Structural loads. They have special profile that produces wall/ceiling/roof/frames with clinched 45mm flange.

- Each Masterikizler Framer is capable of manufacturing walls, stairs, ceilings, floor joists, trusses, and roof frames of a structure. Masterikizler System is the optimum solution up to mid-rise structures.

- Specifications of De-Coilers

- De-coiler scan carries up to 2500 kilograms of steel roller reserve

- De-coilers provide electronic soft start/stop operation and fully self-contained drive system

- Speed is adjustable.

- Forward-Reverse direction is adjustable.

- 3D Design Software

- Our 3D Design Software is a powerful, flexible, and user-friendly tool specially made for light steel framing. All design work can be done in Masterikizler Design, from low level villas to multi-level or split-level complex structures.

- 3D Design Software Properties

- User friendly 3D visual interface

- Helpful geometric tools

- Viewing production processes, sheeting, and perspective of 3D structure

- Importing DXF formatted files

- Automatically creating all structural members with “AutoCreate” function

- Easily creating the 3D structure from 2D architectural drawings or axle line

- Automatic clash check between profiles or between frames, frame geometry and minimum length check functions

- Bill of material reports for steel, rivet/screw usage, cladding areas etc.

- DXF Exports for 3D and plan view, and assembly drawings

- Defining the material properties, point loads, distributed loads and load combinations within software and preparing the SAP2000 export file.

- Calculates support reactions, deflections, and force diagrams for structural analysis

- Exports manufacturing file

- Exports Masterikizler Mobile Viewer file

- Getting arc production file

- Masterikizler Framer Manufacturing Software

- After the design of structure in Masterikizler Design Software, a manufacturing file is exported. This file is loaded to the computer on our Framer, and all parts are manufactured precisely.

- Masterikizler Framer Manufacturing software is Windows based and user friendly. Real time graphics show: parts manufactured (blue), part under manufacture (red) and parts to be manufactured (grey) with intelligent color coding. Also, the production speed can be adjusted on the Masterikizler Framer Software. With this feature, operator can speed up or slow down the machine according to speed of the combining process.

- Also, the production speed can be adjusted on the Masterikizler Framer Software. With this feature, operator can speed up or slow down the machine according to speed of the combining process.

- Hydraulic station operation times, license and language settings can be done in user settings.

- New stations can be added, and heat and temperature values can be seen in the system settings.

- From the Real Time Manufacturing section, user can adjust the production speed, and start, stop, and pause the manufacturing process. The amount of steel usage, number of rivets, production time, remaining time, and real time hydraulic heat –pressure values can be seen in this section.

- Length and station calibration scan be done from the calibration settings.

- Production reports, error reports and material usage reports can be taken from the reporting section

- In simulation mode, all processes made on the profile and the results of them can be seen without actual manufacturing.

| - | General Features of Our Light Steel Profile Production Machine |

|---|---|

| Profile Type | Produces every profile type used in prefabricated building production |

| Stations | 11 |

| Operations | 12 standard operations |

| 1 | Flatten |

| 2 | Service Hole |

| 3 | Notch |

| 4 | Dimpled Rivet / Screw |

| 5 | Swage |

| 6 | Cut |

| 7 | Bolt Hole |

| 8 | Eliptic Hole |

| 9 | Lip Notch |

| 10 | Service Hole 34-50 mm |

| 11 | Index Hole |

| 12 | Chamfer |

| Profile size range | 0.63 mm - 2.5 mm |

| The width of the profile you want to produce from the machine | We prepare your machine according to the profile width you specified. A machine can only produce products with one profile width. (Dimensions such as 63mm, 75mm, 90mm, 100mm, 140mm, 150mm can be given as examples.) |

| Software | Including |

| Production speed | 200m/hr – 750m/hr (The machine speed changes due to the number of operations on the machine.) |

| Servo Motor Power | 5 kW (Can be increased upon request) |

| Hydraulic Motor Power | 7.5 kW |

| Hydraulic Oil Tank | 80 liters |

| Weight | 4.000 kg |